| |

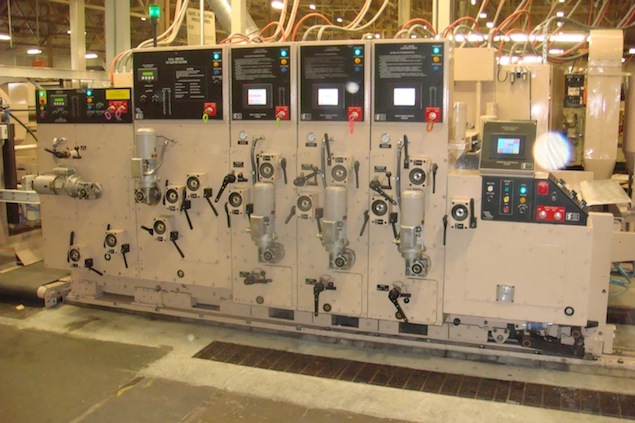

The machine reconditioning will include the following:

- New electric 360 degree running registers with digital read-out on slotter and printers

- 1:1 impression to print ratio with chromed print and impression cyliders, and pull roll shafts

- Chromed slotter and creaser shafts

- Motorized slotter heads and folding rails with new Valco glue system

- New Sun Lead edge feeder with Extend-O-Feed, skipfeed, and vacuum control

- Motorized back stop "in/out" and "up/down"

- Motorized side quides

- Equipped with new gang lock slotter heads with 3/8 slots

- Indepent adjustable folding rail setting for flat sheet runs

- New roll-back mechanism and new roll back tracks and hardened wear strips

- Roll-back slotter for easy set-ups and maintenance, and die cutting after slotting

The machine will be upgraded with the following CMS retrofits:

- New 60 HP digital drive (AC)

- New electrical enclosures throughout

- New electrical with PLC control, includes "auto zero". Touch control screen with register control at the delivery end, and touch screens on the printers and feeder

- Vacuum assisted folding section, H/D folding guides, zero crush folding rollers, and folding rails to skip feed length

- Automatic lower folding belt tensioners

- Heavy-duty no-tools required nylon rod fold

- Extended upper and lowe folding belts (eliminates kidney belts)

- New B/C flute and double wall lift screws

- Heavy-duty Accu-Count air aperated pusher retrofit, electronically controlled for accurated and safe bundle count and bundle ejection

- Easy-Set hold down spring retrofit on squaring bar

- Built-in long and short hold downs in bundle and compression section

- Narrow panel hold down retrofit

- Air operated frame lock, PLC programmed with "auto open", "auto lock" and "auto zero"

- New low voltage air and machine control system

- All keyed gears and perma-mesh drives equipped with extra heavy-duty keyless friction locks

- Printers equipped with no-tools quired Quick-Set pull collars

- Harris & Bruno chambered doctor blade system with easy wash

- Gravity ink feed and pump return (prevents end seal leaks)

- Machine to be professionally stripped and painted to Customer's color specification

Optional, New CMS 701 Stationary Die Cutter, after slotting:

- Chromed die cut cylinder with 5/16-18 tapped holes per OEM standards for die cutting die board mounting

- Chromed lower die cut cylinder with Dicar, auto oscillating, independently driven

- Chromed entrance upper and lower pull roll shafts with CMS Quick-Set pull collars

- Motorized scrap belt system

- Equipped with air brake to prevent register loss when opening machine

- H/D 360 degree harmonic drive electric running register with digital read-out

- Outside register control is disabled when machine is open

- Inside register control for die mounting

- Exit transfer roller section with air curtain and brushes for scrap removal

- Equipped with ring fedder keyless friction locks on the harmonic drive hub, upper pull roll drive gear, and lower pull roll drive flange

- Machine to be wired per Customer's safety standards

- Machine to be painted to Customer's color specification

|